nanoparticles sneak into our lives

The differences between ultrafine dust particles and nanoparticles

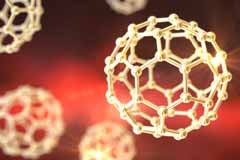

Ultrafine dust is one of the airborne particles with a size of 0.1 micrometer (= 100 nanometers) and smaller. Nanoparticles also belong to this size category, but have additional features. The European Union Cosmetics Regulation covers nanoparticles as follows: Nanomaterial is an insoluble or biologically stable and deliberately produced material with one or more external dimensions of 1 to 100 nanometers. According to the Committee on Hazardous Substances Germany, nanomaterials are deliberately produced, solid, particulate substances consisting of nanoobjects and their aggregates or agglomerates.

In these ways nanoparticles enter the body

Ultrafine dust and nanoparticles enter the lungs via the respiratory tracts and spread over the blood stream due to their small size. They are either excreted or stored in organs. The Irish researcher Kenneth Dawson found that artificially generated nanoparticles are recognized by the immune system. Through an inflammatory reaction, the foreign bodies are degraded as far as possible within a period of a few weeks. Dawson states that studies are urgently needed over a long period of time. In animal experiments in the form of a 90-day inhalation, an inflammatory reaction was also found in rats (Otto Creutzberg).

Challenge for measurement technology

The detection of nanoparticles in the air is a mammoth task. For the measurement of particulate matter particles, high-quality particle counters are required, the costs of which are well above € 10,000. Before the measurement, the boundary conditions and the measuring method must be carefully described, otherwise the results can not be verified in any way. The next hurdle is the differentiation into natural or artificial ultrafine dust and industrialized nanoparticles. While the particle measurement takes place at the site of the formation, the detailed analysis of nanoparticles has hitherto only been possible in the laboratory. The combined TEM / EDX method is used. After previous electrostatic deposition, the image analysis is carried out with the transmission electron microscope (TEM). This is followed by elemental analysis by means of energy-dispersive X-ray spectroscopy (EDX). The description of the measuring method indicates the effort required to display nanoparticles in the air in a verifiable manner. The consumer serves as a test object. For example, if you paint your apartment with a nano-containing wall paint, the effects can not be measured practically. The selection of the products is all the more important.

Measures in the field of occupational safety and health

Since the health effects of nanoparticles are still unclear, there is also a lack of limit values. Although the technical rules for hazardous substances provide for dust protection limits, they do not apply to ultrafine dust. Occupational health and safety firstly focuses on organizational measures. In the operational process, the particles should remain in closed systems. If there is a risk of leakage, it is recommended to wear personal protective equipment. Nano-containing materials or liquids should be marked “Attention – not yet tested”. Employees in vulnerable areas are increasingly involved in health monitoring. The “trial and error” method is used to gain insights into the health effects of nanoparticles at the workplace.

picture source: shutterstock.com